Collection: MEWP Courses

MEWP (Mobile Elevated Work Platform) training is crucial for anyone operating or supervising the use of aerial lifts like boom lifts and scissor lifts. This training ensures workers can safely operate these machines, reducing the risk of accidents and injuries. Training typically covers equipment operation, safety procedures, hazard identification, and fall protection.

Who needs training?

Operators:

Individuals who operate MEWPs such as boom lifts, scissor lifts, and telehandlers.

Supervisors:

Those who oversee MEWP operations, including selecting the correct equipment, understanding regulations, and ensuring safe practices.

Occupants:

Anyone working on the platform, even if they are not operating the machine, needs basic safety instructions.

What does the training cover?

Equipment Familiarization: Understanding the different types of MEWPs, their components, and how to operate them safely.

Safe Operating Procedures: Learning how to maneuver the lift, avoid hazards, and use proper safety equipment.

Fall Protection: Understanding and using fall protection measures, such as harnesses and lanyards, to prevent falls from the platform.

Risk Assessment: Identifying potential hazards on the job site and taking steps to mitigate them.

Emergency Procedures: Knowing how to respond in case of an accident or equipment malfunction.

Regulations and Standards: Understanding relevant OSHA and ANSI standards for MEWP operation.

Important Considerations:

Qualified Trainers:

Training should be conducted by qualified individuals with expertise in MEWP operation and safety.

Specific Equipment Training:

Operators should receive training on the specific type of MEWP they will be using, including its unique features and controls.

Practical Evaluations:

Hands-on evaluations are crucial to ensure operators can safely operate the equipment.

Retraining:

Retraining may be necessary if there are changes in regulations, equipment, or if an operator's proficiency declines.

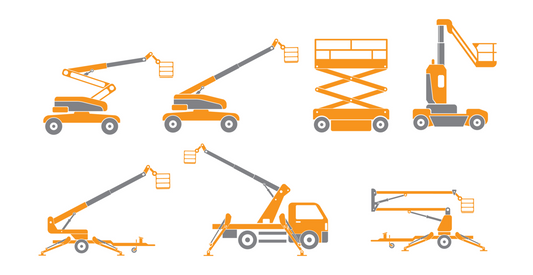

MEWP Categories

Mobile Elevating Work Platforms (MEWPs) are categorized into Groups (A or B) and Types (1, 2, or 3), based on their platform design and movement capabilities. Group A MEWPs, like scissor lifts, have platforms that stay within the tipping line, while Group B MEWPs, like boom lifts, can extend beyond it. Type 1 MEWPs can only travel when the platform is stowed, Type 2 can travel elevated but controlled from the chassis, and Type 3 can travel elevated and controlled from the platform.

Here's a more detailed breakdown:

Groups:

Group A:

These MEWPs have platforms that remain within the machine's tipping line (e.g., scissor lifts, vertical personnel platforms).

Group B:

These MEWPs have platforms that can extend beyond the machine's tipping line (e.g., boom lifts).

Types:

Type 1: Can only travel when the platform is in the stowed (lowered) position.

Type 2: Can travel with the platform elevated, but the controls are located on the chassis.

Type 3: Can travel with the platform elevated, and the controls are located on the platform itself.

Common MEWP Types:

Scissor Lifts:

Provide vertical movement, often used for indoor maintenance and construction.

Boom Lifts:

Offer both vertical and horizontal reach, useful for navigating obstacles and reaching high locations.

Vertical Personnel Lifts:

Compact lifts for reaching limited heights, suitable for tight spaces.

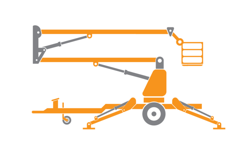

Track Mounts (Spider Lifts):

Designed for uneven terrain, offering stability on slopes and delicate surfaces.

Truck Mounts (Lorry Platforms):

Mounted on trucks, ideal for projects requiring mobility and high reach.

-

Aerial Lift Training

Regular price $1.00 USDRegular price -

Man Lift Training Online

Regular price $1.00 USDRegular price -

MEWP Certification Online

Regular price $1.00 USDRegular price -

Scissor Lift Training

Regular price $0.00 USDRegular price -

Boom Lift Training

Regular price $1.00 USDRegular price